hardness test lab report

LABORATORY REPORT NUMBER 002. A small dent or a scratchRockwell and Brinell are popular hardness testing methods In a.

Experiment 6 Hardness Test A The Purpose Of This Test Is To

RESULTS DISCUSSION Results Parameters First Reading Second Reading Third Reading D1 µm 1531 1517 1535 D2 µm 1590 1517 1535 Hardness HV 1523 1611 1574 Average.

. Hardness Testing Quang Nguyen School of Engineering Grand Valley State University Laboratory Module 4 EGR 250 Material Science Engineering Section 902 Instructor. 1 Tables recording the readings and hardness number of all the specimens refer to the Log Sheet 2 Plot of Hardness v Carbon Content for the Plain. DEPARTMENT OF MECHANICAL AND MANUFACTURING ENGINEERING.

Experiments with predetermined values of process parameters the tensile strength is measured and the micro hardness is measured. A small dent or a scratchRockwell and Brinell are popular hardness testing methods In a. Micro Hardness Lab Report.

A Keep the loading and unloading lever at position A which is unloading position. Include the following information in the laboratory report. Professor Lindsay Corneal October 27 2016 Abstract The purpose of this experiment were to utilize the hardness as an index of mechanical properties to relate the mechanical properties of ferrous and metal to.

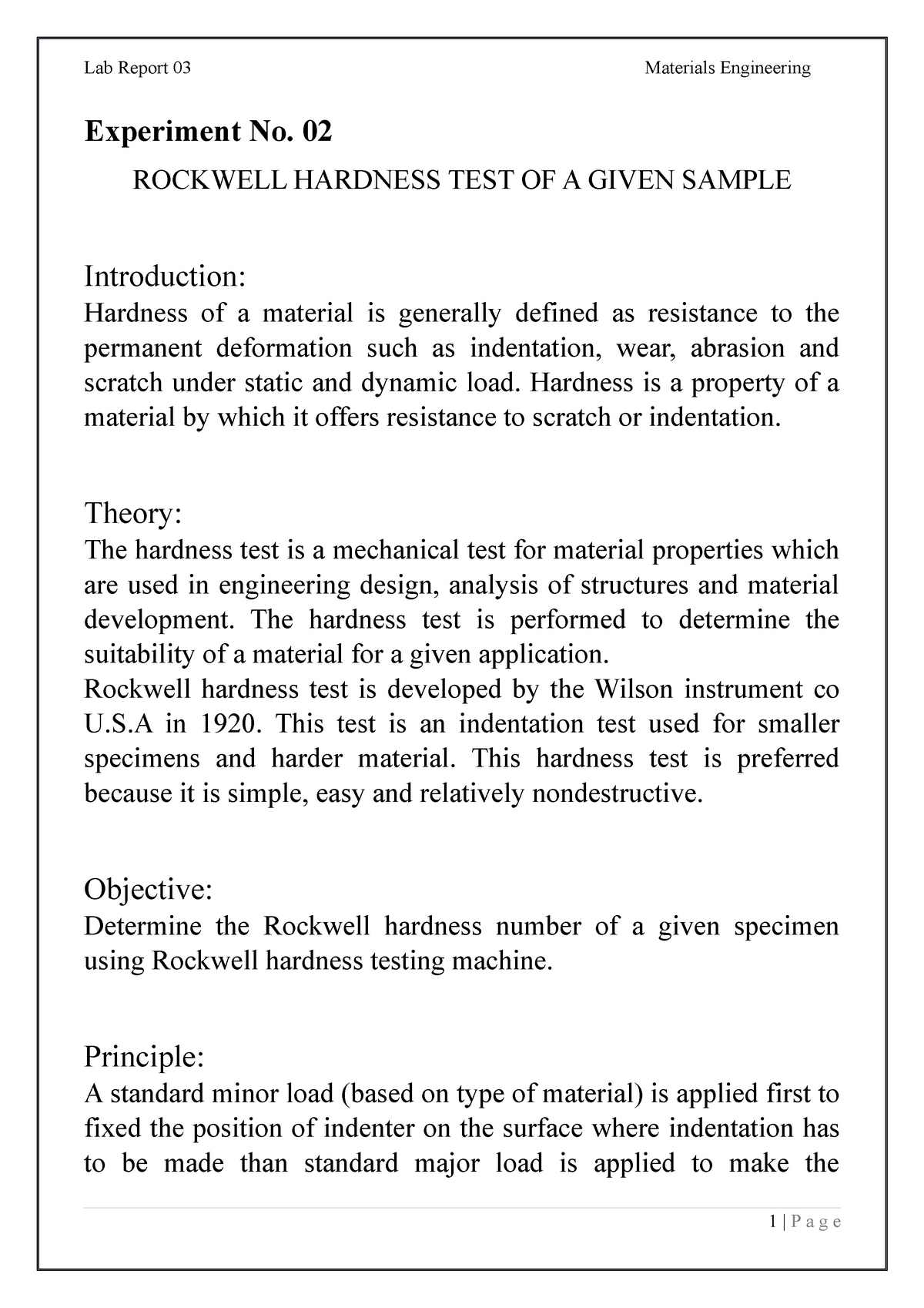

Rockwell Hardness Testing Lab Report Sample. After that the diameter of the indentation d mm is measured when the load is removed. Hardness testing is employed as a non-destructive testing NDT technique on materials.

Create Legally Binding Electronic Signatures on Any Device. HB 2F πD D- D-d Here. Lab report of Rockwell hardness test By.

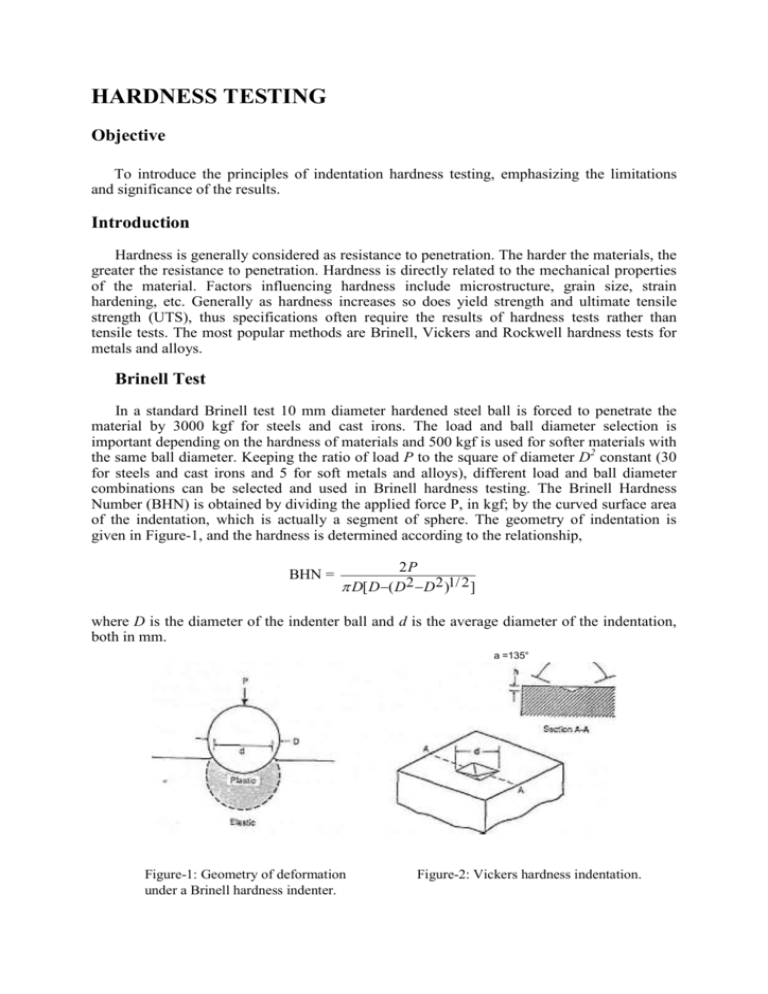

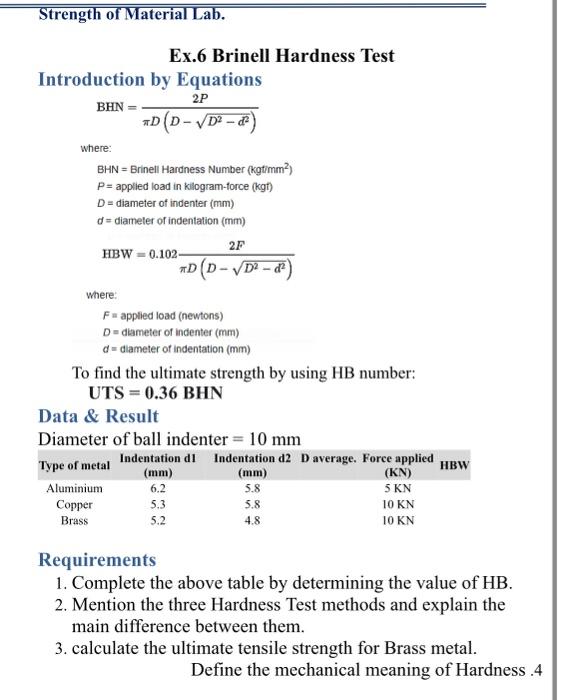

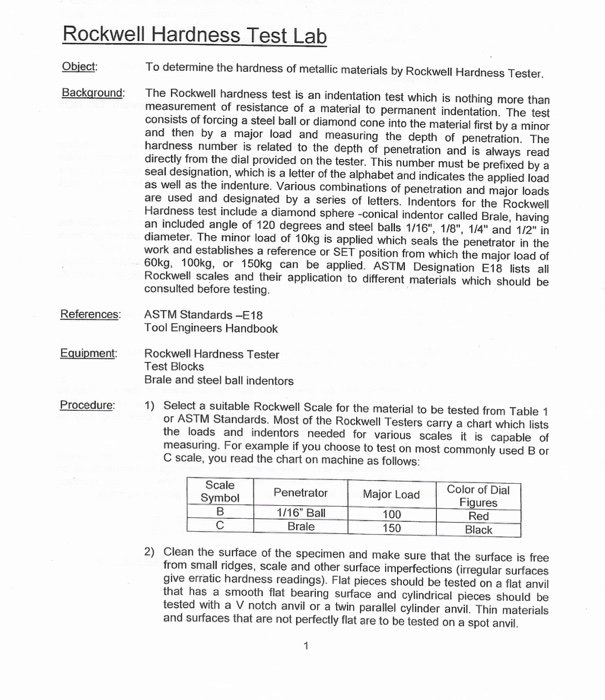

The Brinell hardness number HB is obtained by dividing the size of the load applied by the surface area of the spherical indentation A mm2. The force applied by the hardness tester is set to 10kN and pressure applied to the specimen metal for 10 seconds. B Select suitable indentor weights.

To understand what hardness is and how it can be used to indicate some Properties of materials. The Brinell Hardness Number BHN is obtained by dividing the applied force P in kgf. It can be used to check if the correct heat treatment was conducted on steels and.

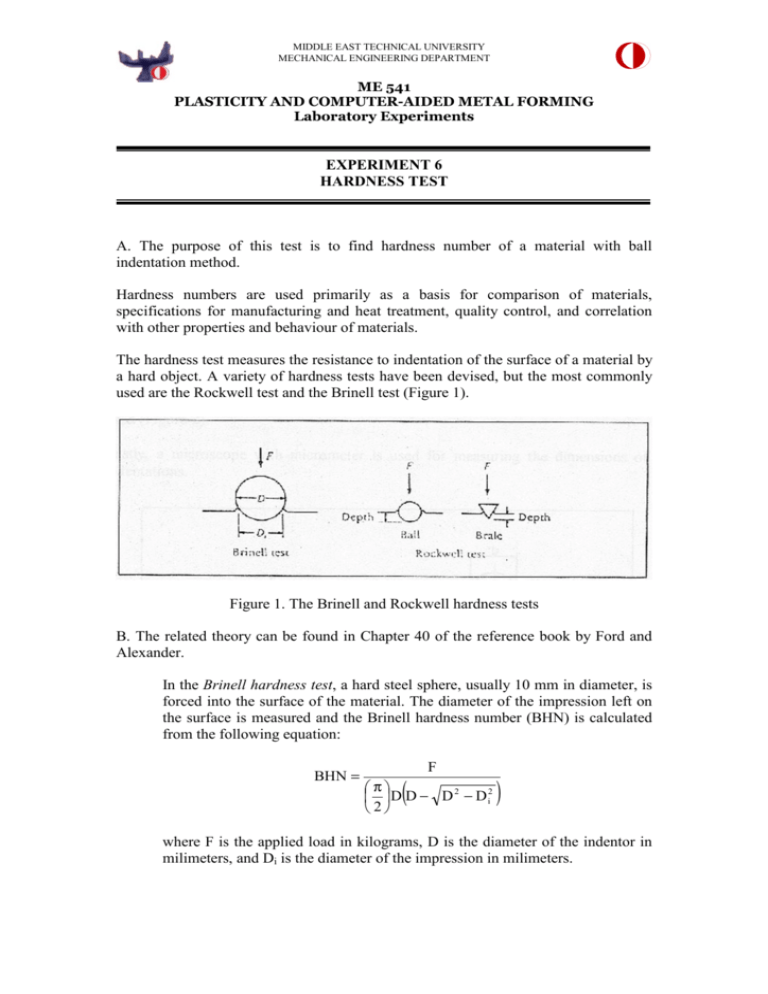

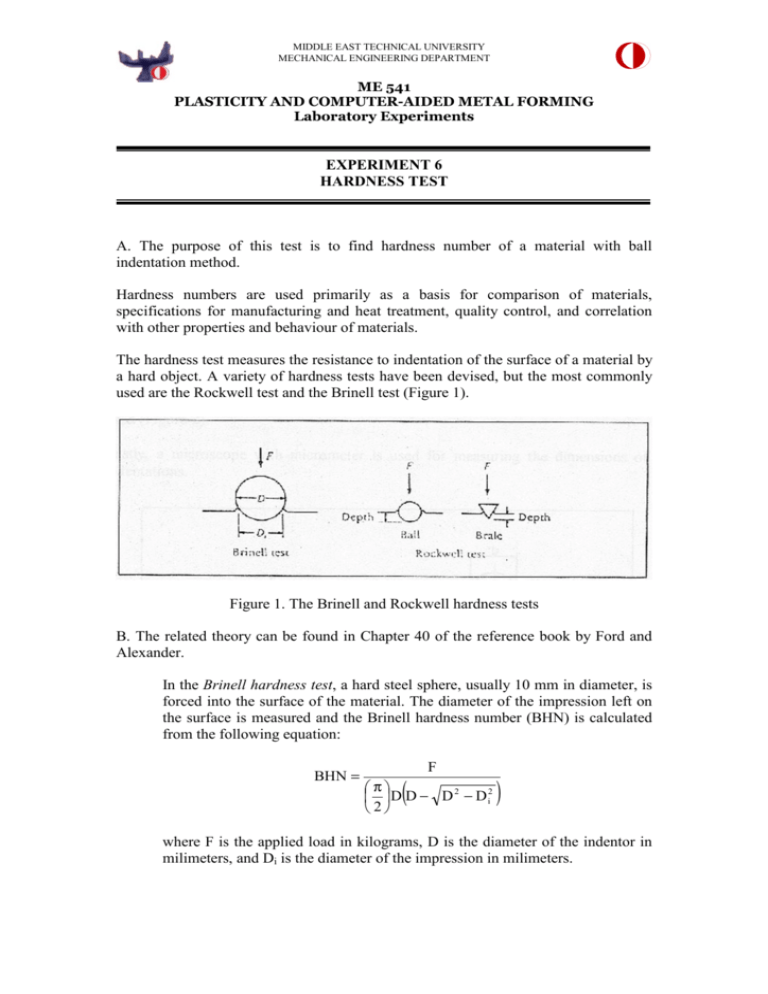

Brinell Hardness Test For Brinell hardness test. The deformation behavior of Tl3AsSe3 TAS single crystals has been studied by hardness tests in four different crystal surfaces the 10overline 10 1overline 210 0001 and the. Compare results of the hardness tests for each metal to book values from a source such as the ASM Metals Handbook.

INDENTATION OF A METAL BY A BALL. Rockwell hardness testing machine. The hardness of materials are test by pressing a steel ball or tungsten carbide ball for a time of 10 to 15 seconds into the surface of specimen by a standard load F kgf.

The specimen Al 2024 which was consist of 38-49 Cu 12-18 Mg 03-09 Mn and Fe Cr Zn Ti in a little amount had been inserted into a. The results should contain. Hardness Test Lab Report.

To conduct this hardness tests we. The purpose of this lab is to ascertain the hardness of two different materials. Rockwell Hardness Test The Rockwell test differs.

Hardness is a measure of a materials resistance to localized plastic deformation eg. Hardness is a measure of a materials resistance to localized plastic deformation eg. Cavity diameter measured from the Brinell hardness machine is converted into the Brinell hardness number by the help of following formula.

ENG60504 PROPERTIES AND APPLICATIONS OF MATERIALS LAB REPORT. Hardness Testing Lab Report. Hardness Testing Lab Report.

For soft or very hard materials the Brinell test cannot be used. By the curved surface area of the indentation which is actually a segment of sphere. Due Date- 972017 Introduction.

One material is aluminum the other will be. Up to a hardness value of about 300 HV the hardness value number given by the Vickers test is the same as that given by the brinell test. Subsequently the diameter of the impression on the sample.

The materials and the. The purpose of the following experiments is to study the hardness of different types of materials and to. Ad signNow allows users to edit sign fill and share all type of documents online.

Hardness Testing Lab Report study the hardness of different types of materials and to understand the significance of this property in materials. Where h mm is the depth of indentation D mm is the diameter of the ball. View Lab Report Hardness testpdf from ENGR 2023 at Sunway University College.

The purpose of the following experiments is to study the hardness of different types of materials and to understand the significance of this property in materials.

Solution Hardness Test Lab Report Studypool

Solved Strength Of Material Lab 2p Ex 6 Brinell Hardness Chegg Com

Doc Experiment 3 Hardness Test Min Yih Academia Edu

Lab Report 03 Experiment No 02 Rockwell Hardness Test Of A Given Sample Introduction Hardness Of Studocu

Solved In Your Report Please Prepare A Laboratory Report Chegg Com

Lab Report For Experiment No1 Docx Lab Report For Experiment No 1 Brinell Hardness Test Objective In This Laboratory The Objective Is To Measure The Course Hero

Hardness Experiment Reading Assignment Callister Section 6 10

Ch Har2 2 Me 336 102 Lab 2 Hardness Abstract The Objective Of This Experiment Is To Become Familiar With The Rockwell Hardness Test And Be Able To Course Hero

Solution Hardness Test Lab Report Studypool

Solved Rockwell Hardness Test Lab Object Background The Chegg Com

Doc Experiment 3 Hardness Test Siti Syairah Academia Edu

Doc Lab 1 Hussain Ahmad Academia Edu

Experiment Rockwell Hardness Test 1 0 Objectives 1 1 Chegg Com

Pdf Laboratory Manual For Hardness Test

Solution Engineering Lab Report Hardness Test Studypool

Solution Hardness Test Lab Report Studypool

168547658 Hardness Test Lab Report Pdf Objective To Determine The Hardness Of Various Engineering Studocu